TM3

Adaptable, Dynamic and Versatile

3 PART FIT SYSTEM

The TM3 is built to be hyper versatile whether you're hitting a monster kicker, pressing a box, floating through knee deep pow or riding hard pack groomers. The boot shell is designed to enhance flex and durability, while the new injection molded liners provides unparalleled support with a customizable fit. Tune your flex based on your riding needs for more response or a softer flex when you need a little wiggle room. The TM3 is adaptable, dynamic and versatile.

MY ROLE

Lead Designer

Color, material and finish

Merchandiser

Product line manager

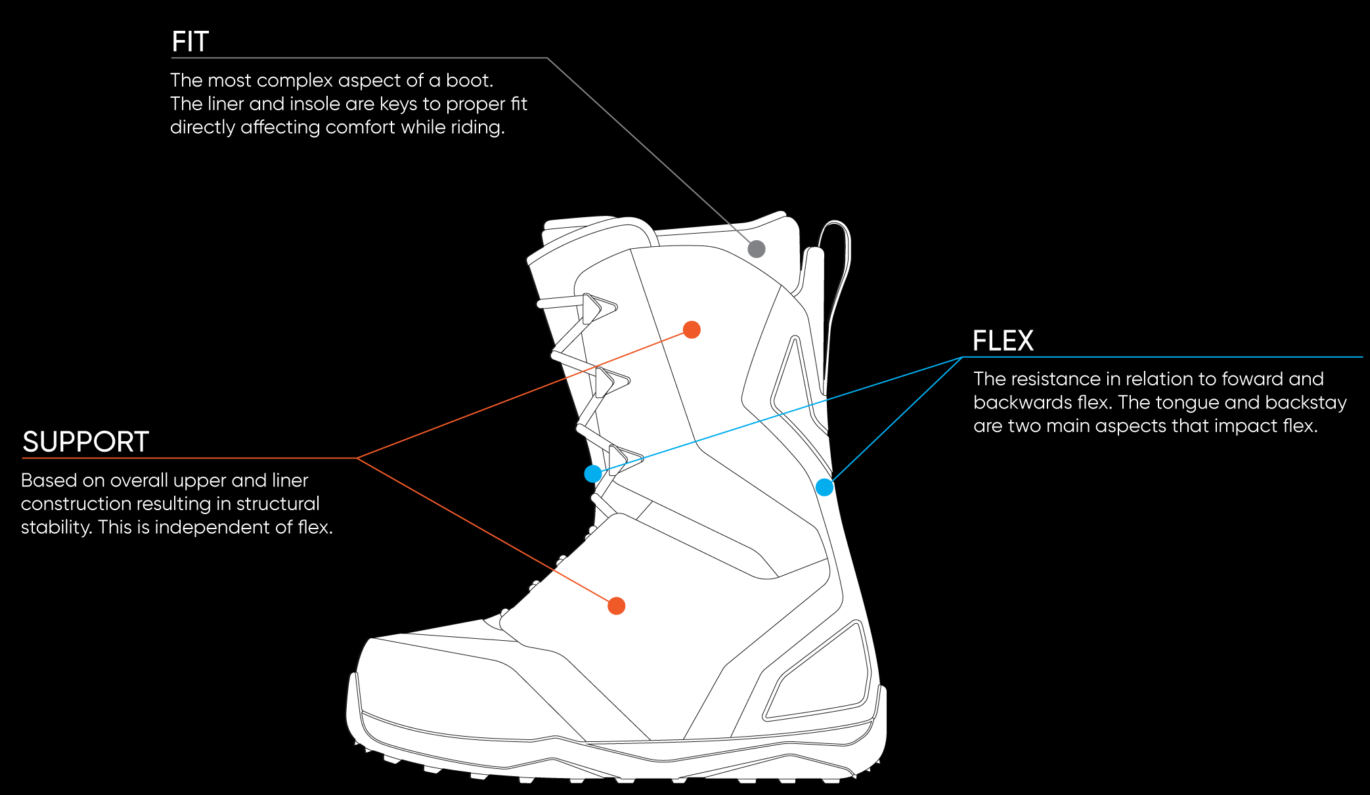

FIT SYSTEM

THE CHALLENGE

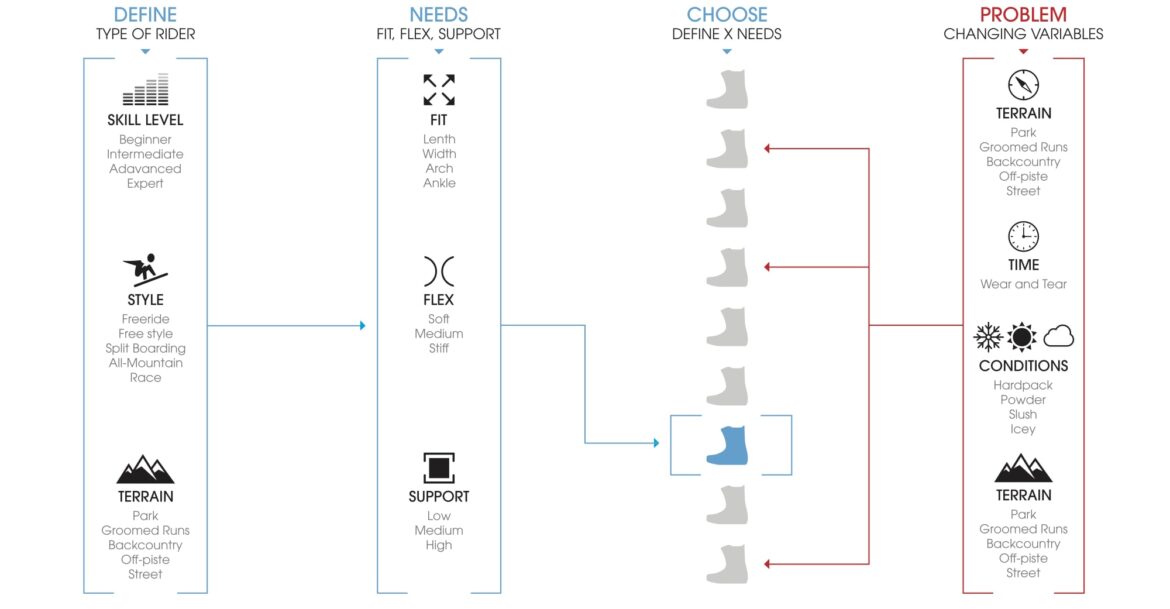

Riders must constantly adapt to Mother Nature. Traveling with various types of boards, goggles and outerwear for daily changing conditions and terrain. However, riders are limited with the boot, relying on one pair with a fixed fit, flex and support for unpredictable environments.

The challenge is to create a 3 part fit system for a new halo product and brand driver that is technically driven and customizable for both in-store experience and tunable fit for ever changing the rider's needs on the mountain.

HIGH LEVEL GOALS:

- Boot Upper - Enhance movement, support and durability

- Boot Liner - Maintain structural integrity and fit

- Flex Control - Customizable flex

- Footbed - Adaptable arch support

PART 1 - BOOT UPPER

A BOOT THAT MOVES WITH YOU

THE CHALLENGE

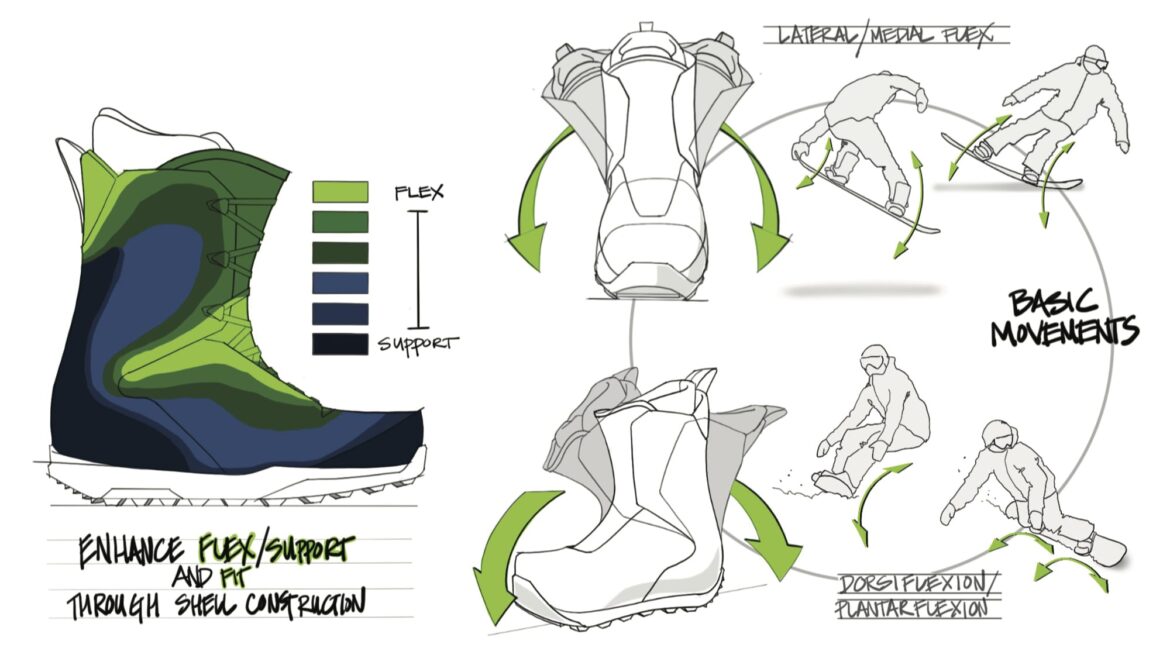

With traditional upper construction flex and support are in direct correlation: the softer the flex the less supportive the upper. Softer boots break down faster while stiff boots restrict too much movement. Flex and support should be independent allowing boots with a soft flex and high support and vice versa. Riders who need a soft flex are at a disadvantage with boots that have a shorter life cycle.

Design a soft flexing upper allowing for freedom of movement with high support that enhances shell durability prolonging the life of the boot.

HIGH LEVEL GOALS:

- Movement - Enhance the movement of the rider

- Support - Strengthen the shell in key zones for rider confidence

- Durability - Prevent early boot breakdown and shell distortion

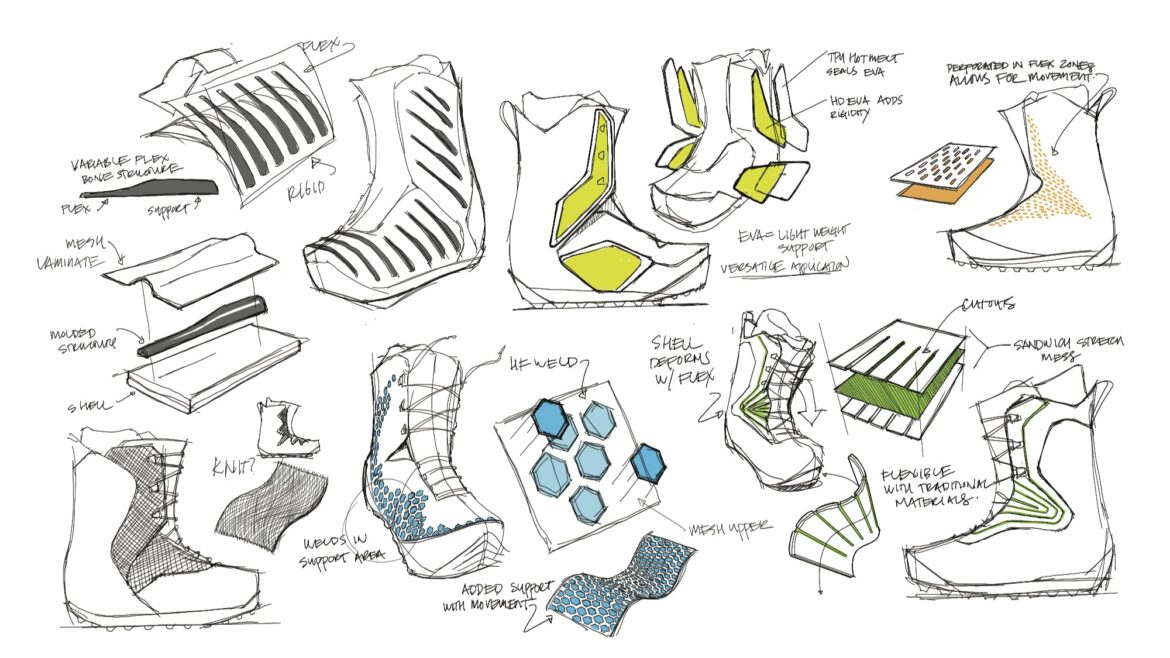

ARMORED FLEXIBILITY

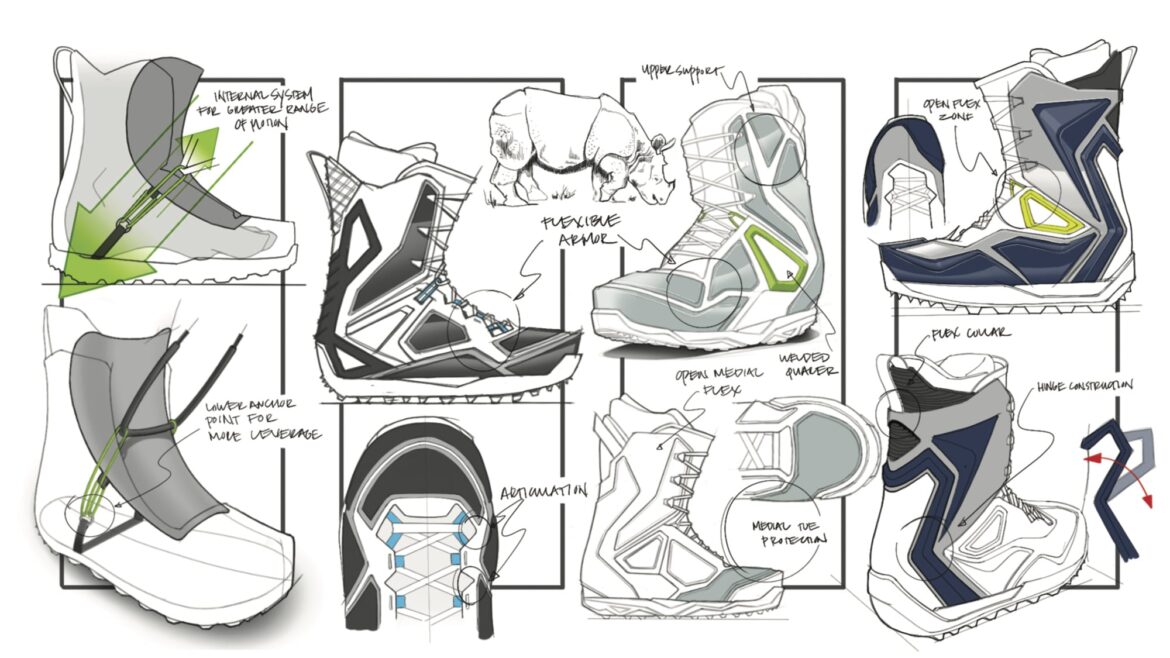

IDEATION

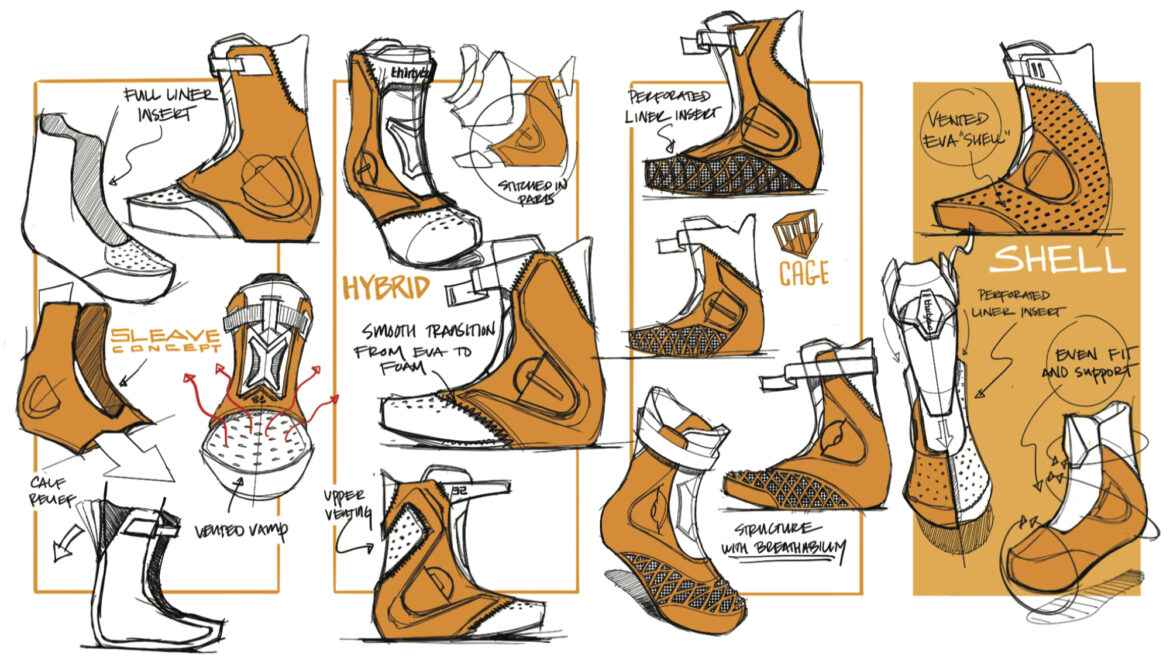

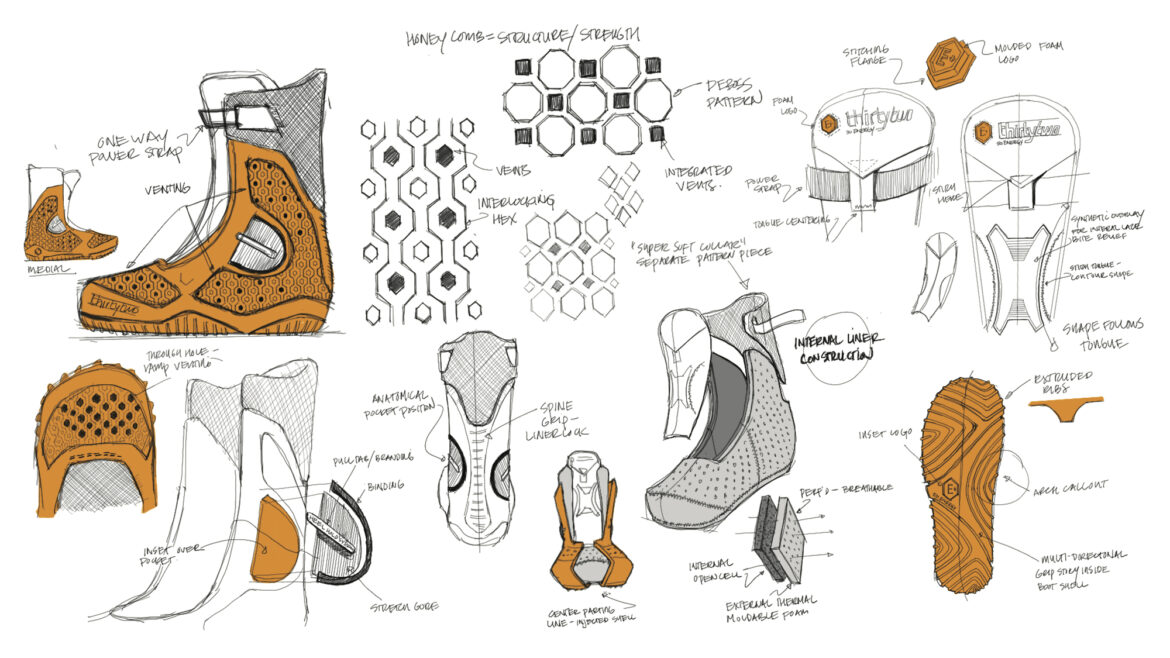

Exploration of material and construction applications to allow for dynamic movements while still adding support to the upper. Using a layered combination of TPU laminate with varying EVA densities, support and flex can be controlled by strategic placement and application on the upper.

Laminates can be placed in flex zones to reinforce areas of high wear or removed in flex zones to allow full movement. The TPU laminate acts as a waterproof barrier and is more durable than textile or synthetic materials used in shell construction.

Connecting ways to enhance the shell for durability while still maintaining flexibility

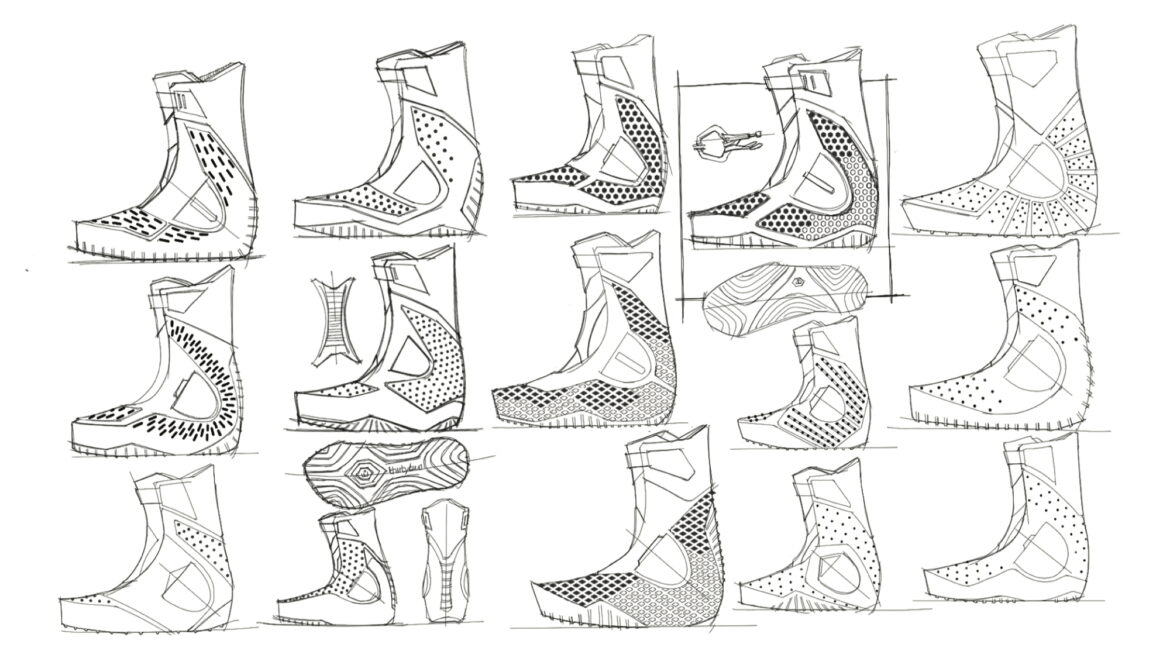

Placement options on boot shell that allow for armored protection and support while negative space allows the boot to move freely.

Expanding on the armored protection concept with a leverage lace system utilizing the boot tongue for heel lockdown

Refining the armored protection concept focusing on the key flex and support zone

MUTLI-LEVEL TRACTION

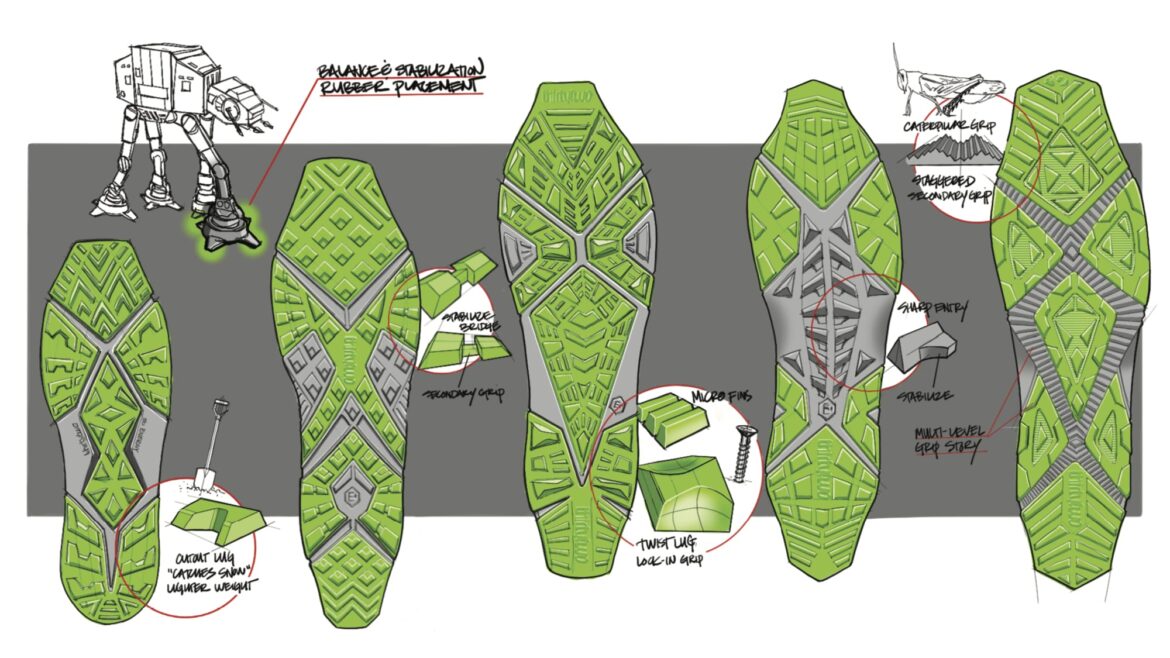

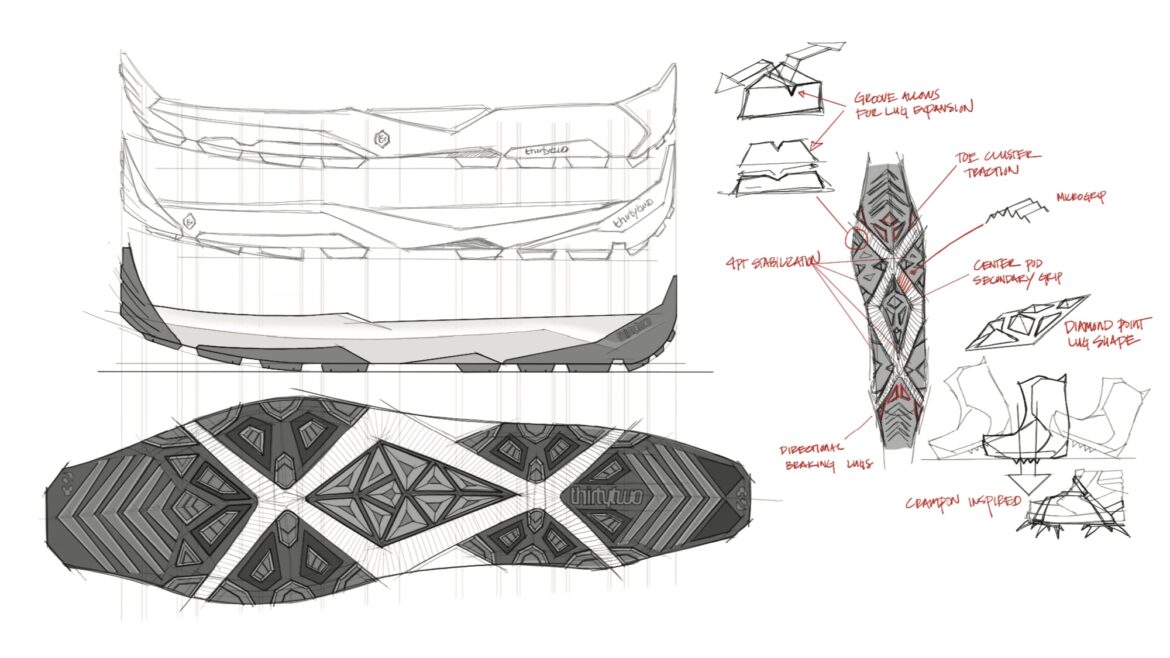

IDEATION OUTSOLE

Initial tread pattern and lug shape exploration focused on multi-directional grip. The final direction - inspired by the serrate legs of grasshoppers - emphasized a mutli-level grip and traction story providing mirco traction while larger lug shapes add stability for the user.

Outsole tread exploration focusing stability

Multi-level grip and traction concept

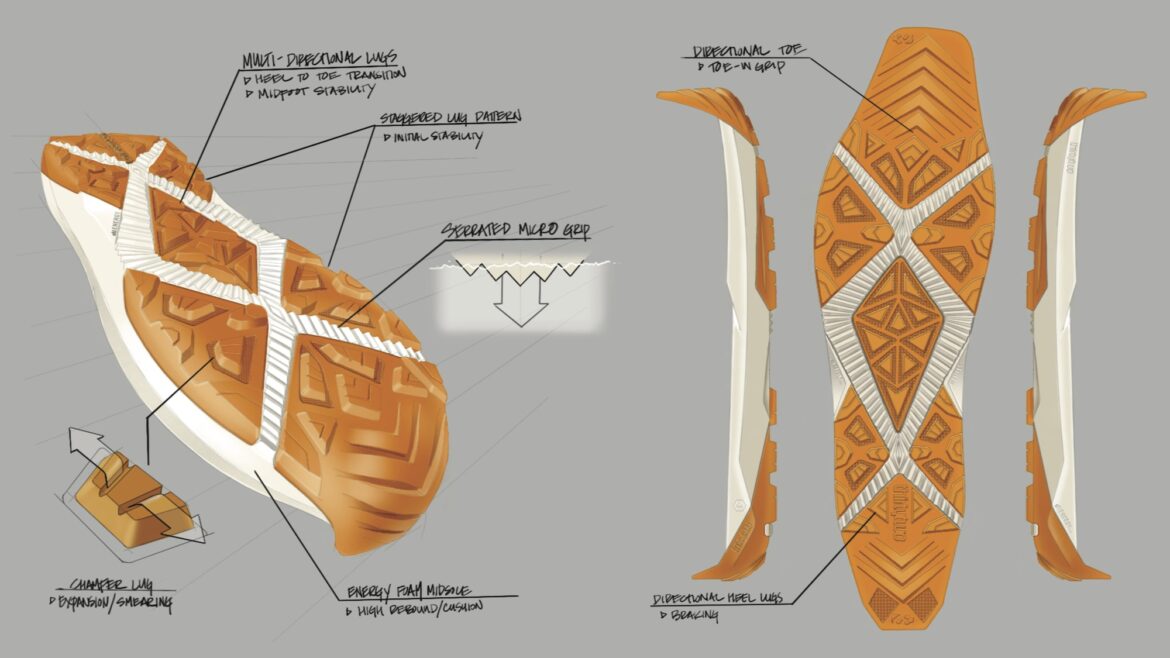

ENHANCED FLEX SUPPORT AND DURABILITY

BOOT FINAL DESIGN

Utilizing a simple but effective layered approach to solve the issue of a free flexing boot with high support. Strategically placed EVA and TPU on top of a textile base in key wear areas and sections that enhance support. Open textile panels and deboss details allow for maximum flexibility and movement. The material applications and placement communicated the functionality of the boot.

- Movement - Minimizing layers in flex areas and enhancing support zones accentuating and facilitating movement

- Support - Overlays in key support zone enhances stability without negatively impacting flex

- Durability - Utilizing TPU hotmelt and high density EVA for additional protection on exposed sections of the upper

Strategically placed overlays for support and flex

Medial side and toe down durability and lock down features

Shell construction built for flex and movement

Internal support story emphasizing heel lock down

Multi-directional tread with a combination of rubber pods and EVA serrated traction prevents side slipping and enhances grip

PART 2 - LINER

JUST NOT A GOOD FIT

LINER CHALLENGE

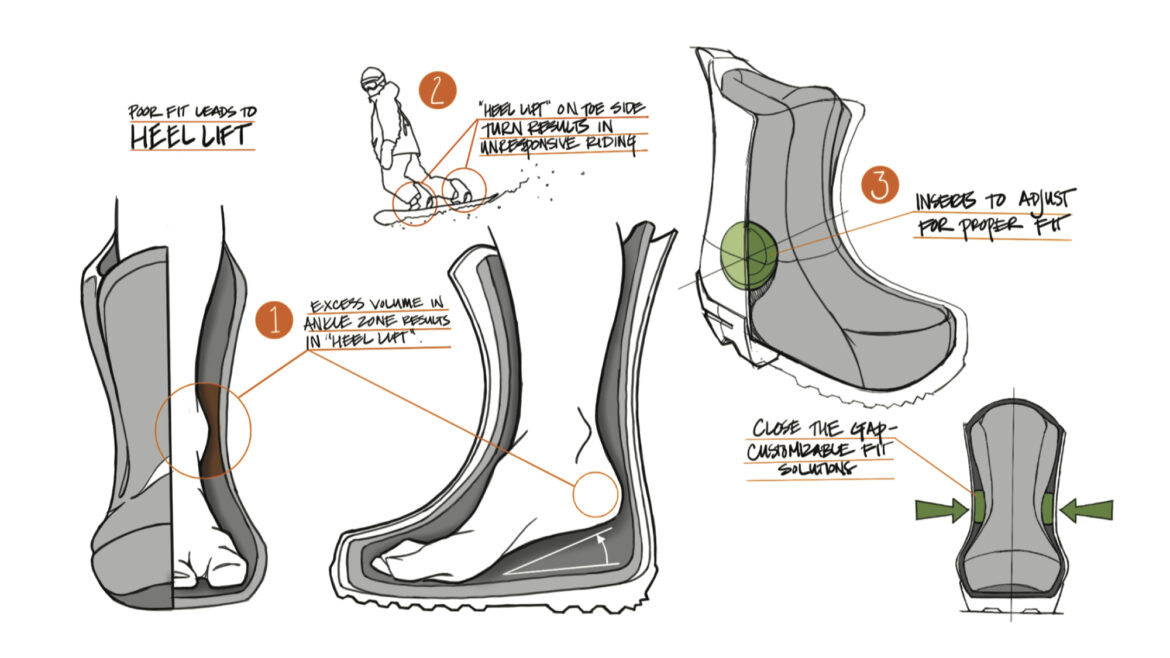

Liner construction is challenging because it is in direct contact with the foot. Liners must consider different ankle shapes, Liners are built with soft, low quality foams with priority placed on comfort not performance. The foam breaks down and packs out quickly resulting in improperly fitting boots. Ill-fitting liners are uncomfortable and cause heel lift which impacts response while riding.

The challenge is to design a high performance liner that maintains fit and structure over multiple seasons. Accounting for heel lift, comfort and overall responsiveness.

HIGH LEVEL GOALS:

- Fit - Reduce heel lift and maintain heat molding features

- Structure - Maintain shape and prevent deformation

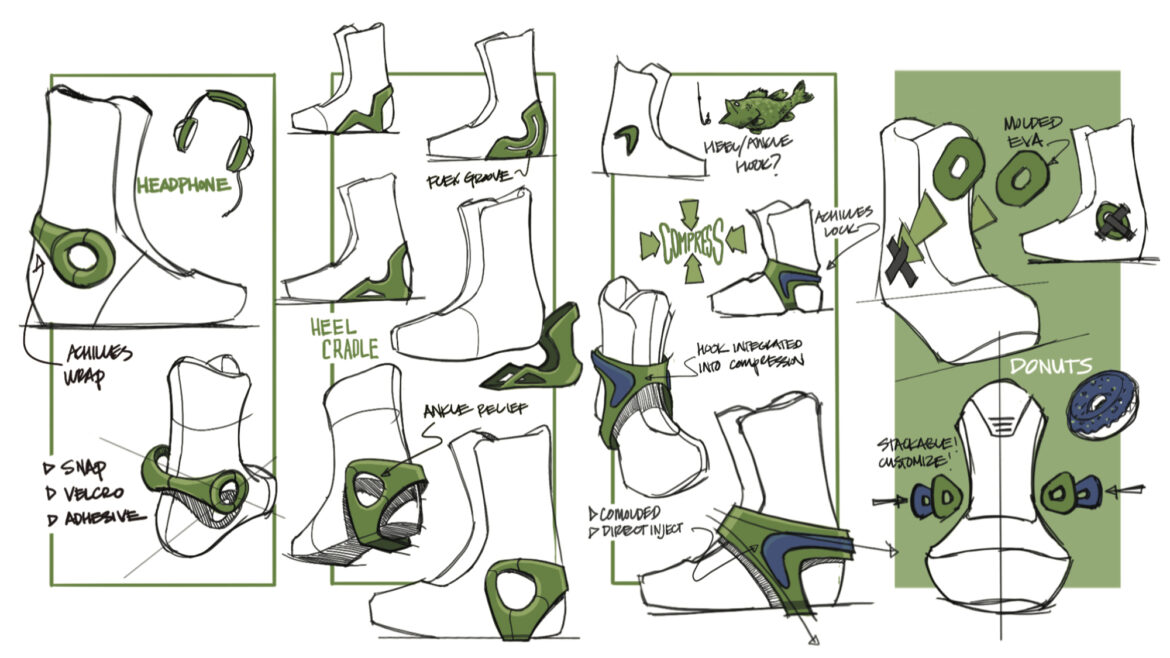

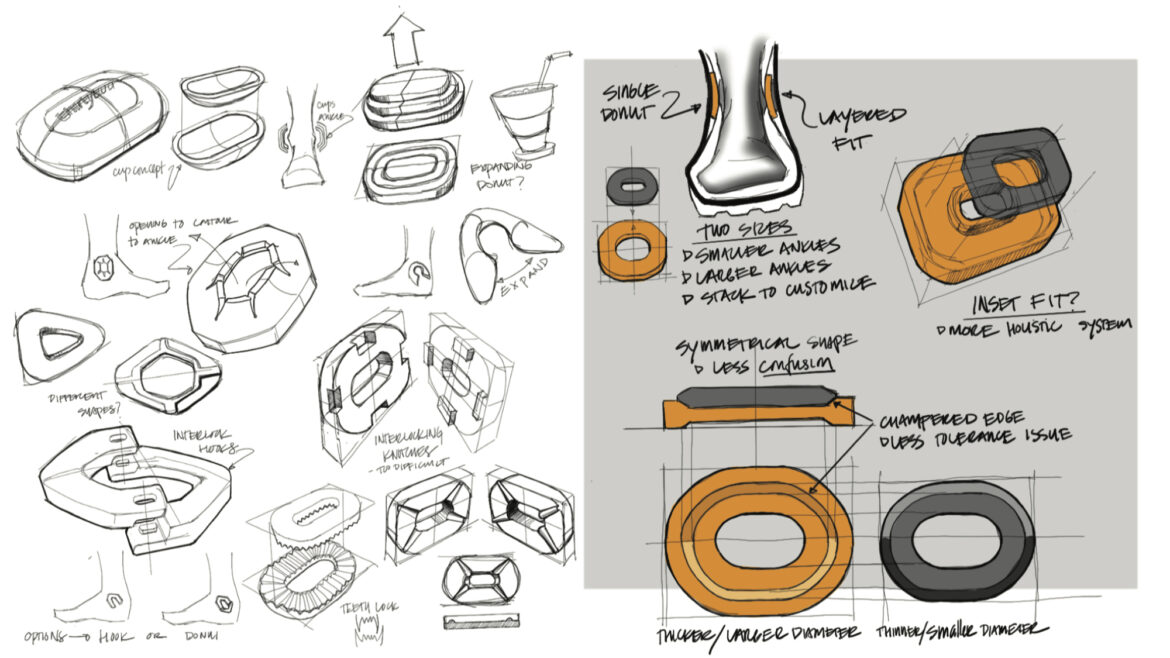

STACKABLE DONUTS

HEEL LIFT IDEATION

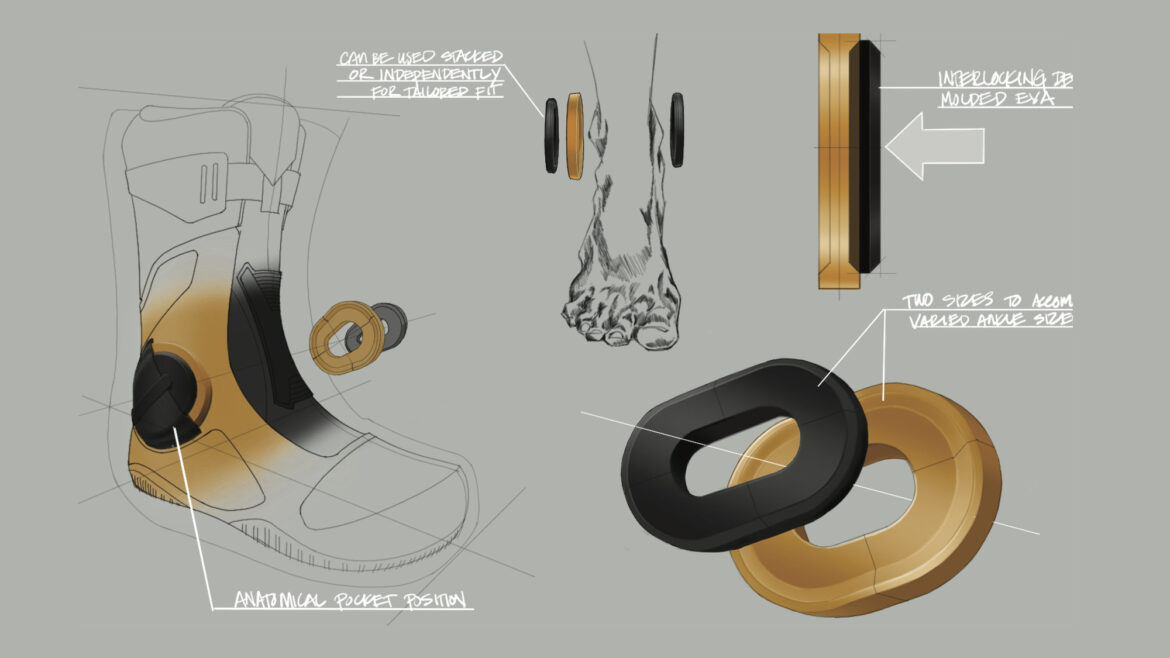

Heel hold is typically a result of narrow ankles and excess volume in the liner and boot. Ideation explores different solutions to add concentrated volume or to compress the ankle zone.

Ultimately, anatomically placed nesting EVA donuts were developed. This concept allows for varying thicknesses and full customization, locking down ankle and preventing heel lift.

Concept solutions for varying ankle sizes

Refining stackable donut solution for a dialed fit

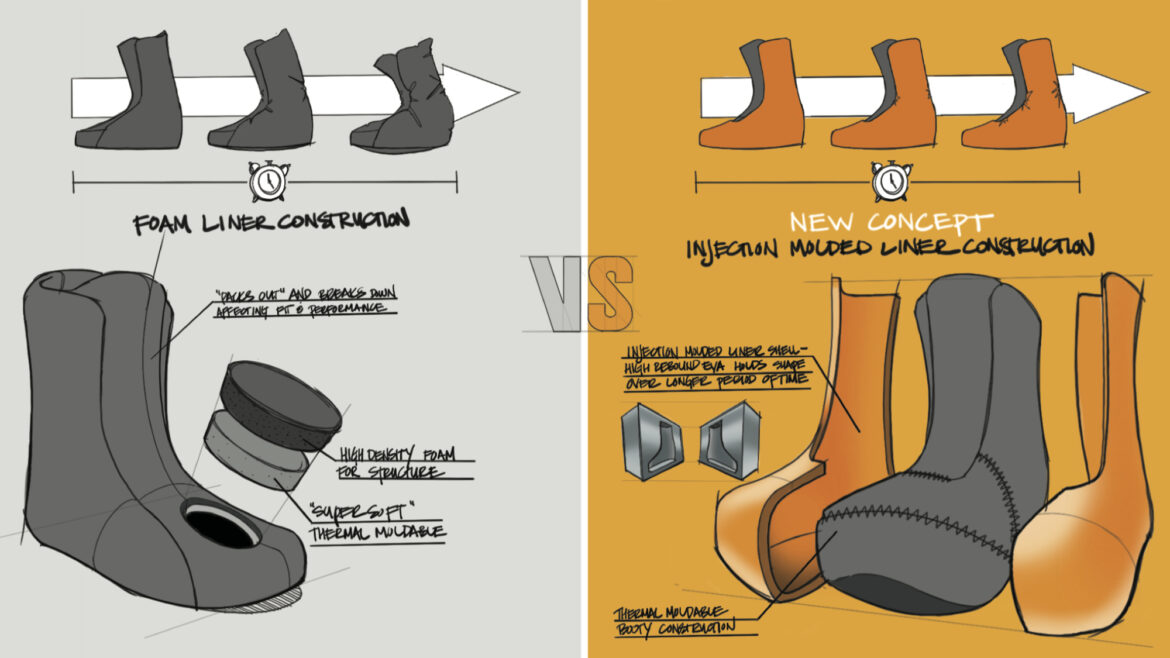

OUT WITH THE OLD

LINER CONCEPT

Traditional liners are constructed with a high density EVA outer layer and softer inner layer that can mold to the rider's lower leg. Overtime the EVA breaks down resulting in an ill-fitting liner compromising performance and fit.

The new liner proposal is an injection molded "shell" and thermal moldable inner foam layer. This concept is more durable and less susceptible to breaking down often times outlasting the life of the snow boot.

Updating the snow boot liner with a longer lasting injection molded construction

LET IT BREATH

LINER IDEATION

The draw back to an injection molded construction is the lack of breathability. This leads to condensation and "swamp feet" in the the liner, once the moisture cools the feet get cold. A venting system is needed to expend the trapped heat in the liner.

Concepts for venting systems in the injection molded liners

Exploring venting perforation patterns in the injection molded liner

Refining and detailing construction, closure and visual language

PUTTING IT ALL TOGETHER

LINER FINAL DESIGN

Utilizing a high rebound injection EVA material, the liner becomes ultra responsive while outlasting the snow boot itself. The upper portion of the liner maintains traditional liner construction preventing calf bite while the vents allow for a comfortable temperature in the boot.

The Heel Hold Kit combined with a thermal moldable inner layer allows for a customizable fit for varying ankle, calf and feet sizes

- Fit - Heel hold donuts for varying ankle sizes

- Structure - Injection molded liner shell

Integrating the heel hold it with a new high density EVA injection molded liner

HD EVA shell with vented internal thermal moldable foam package

Anatomically correct Heel Hold Kit to reduce heel lift

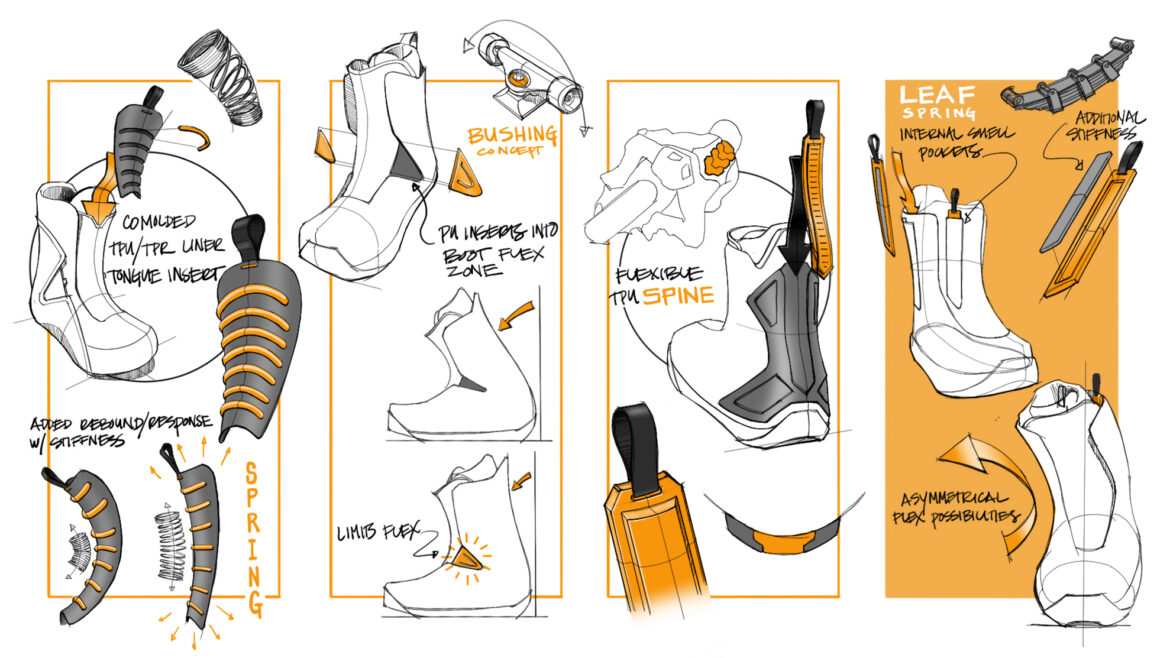

PART 3 - FLEX CONTROL

CUSTOMIZE FLEX

FLEX CHALLENGE

Integrate a flex system into the snow boot that allows the rider to tune for added stiffness.

HIGH LEVEL GOALS:

- Tailored Flex- Adaptable to changing terrain and skill

MIND THE GAP

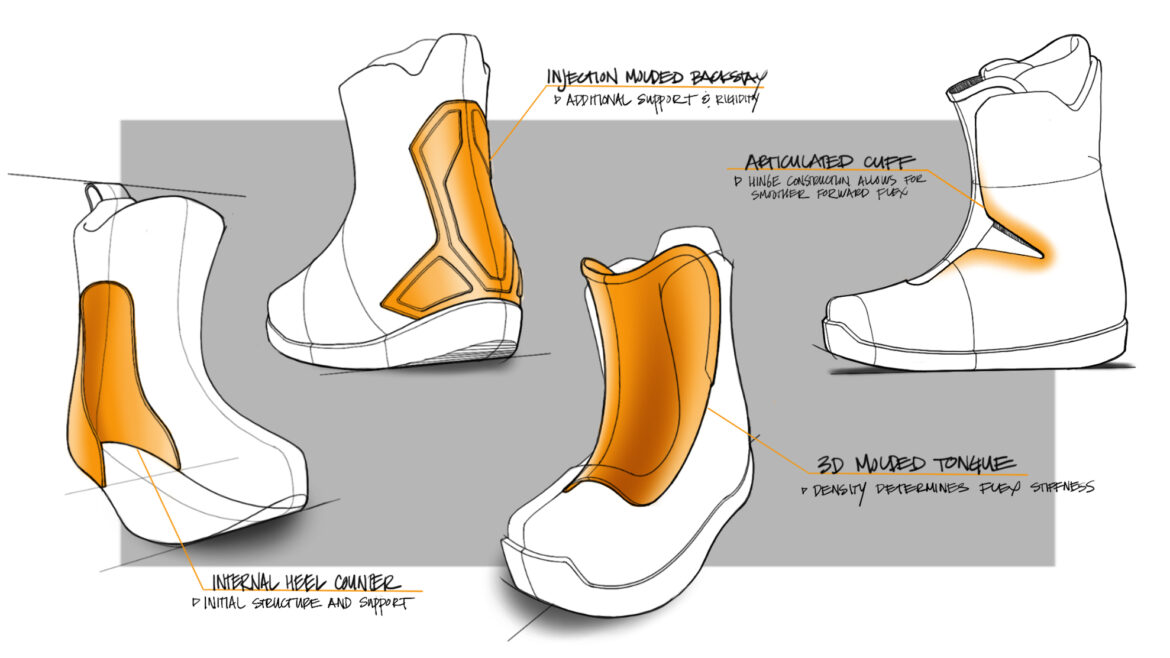

FLEX EXLPAINED

Many components of the boot can impact overall flex: internal heel counter, molded backstay spine, tongue density and cutouts in the upper to allow for a smoother flex. Any combinations of these integrated into the snow boot will change the overall flex and riding experience

Components that impact boot flex

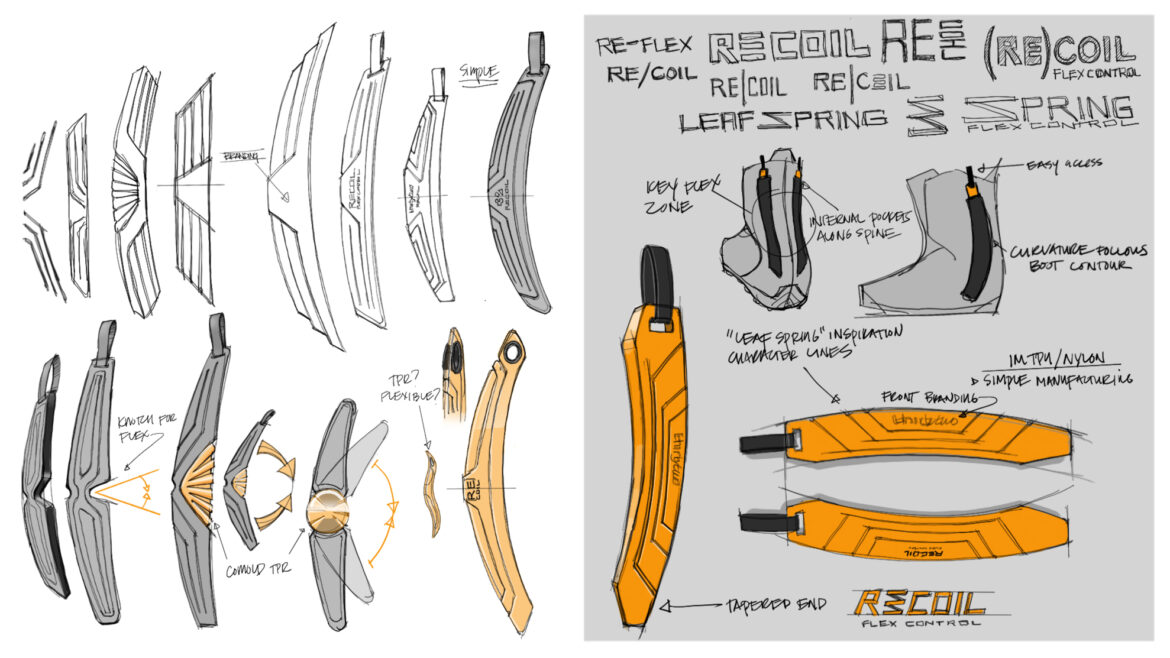

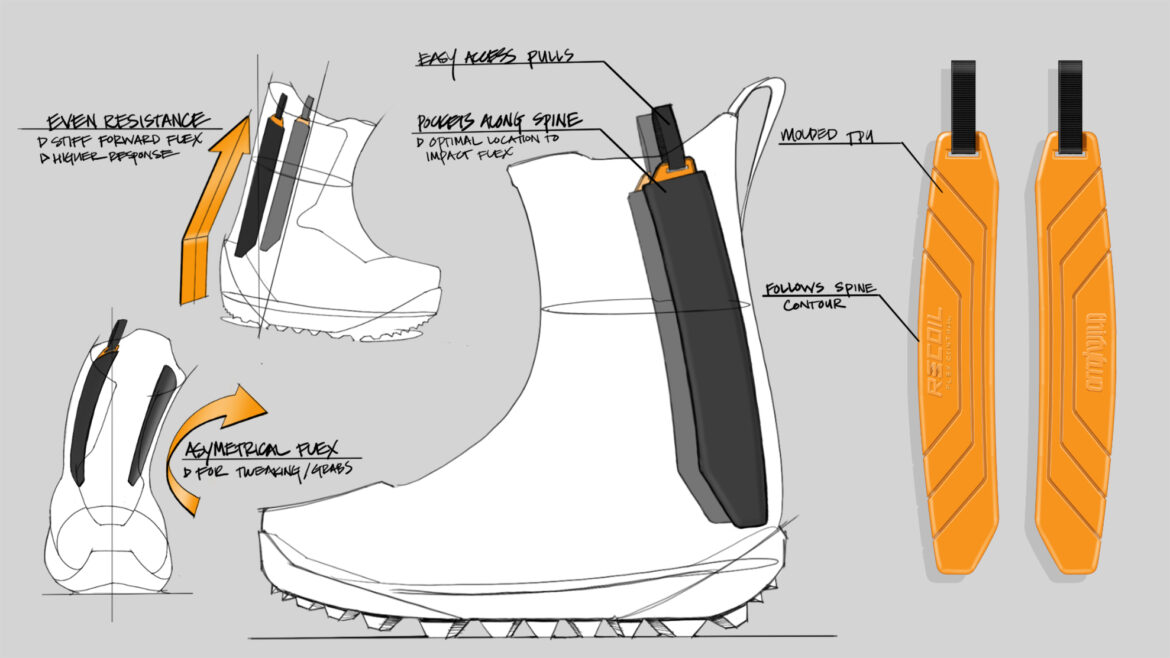

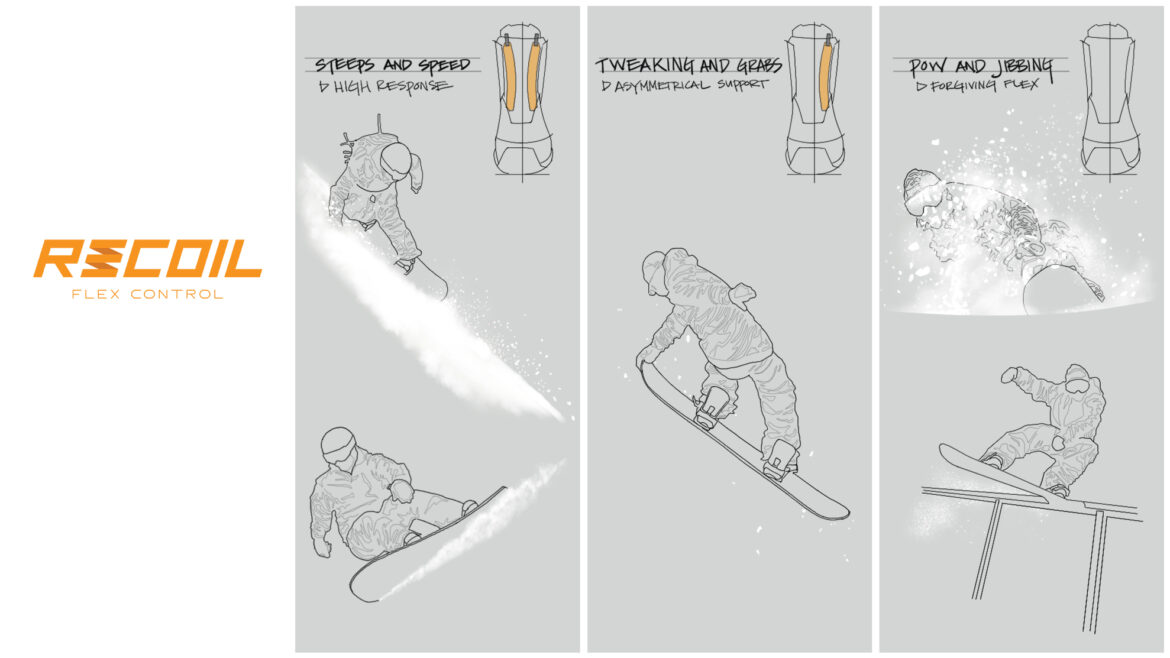

RECOIL

FLEX FINAL DESIGN

Recoil gives the user the ability to tune the flex of the boot based of preferred stiffness and terrain. The flex bars are inserted into pockets on the inside of the boot shell. Asymmetrical flex can also achieved for tweaking or symmetrically for higher responsiveness. Recoil can also be used when the boot shell begins to breakdown and lose its stiffness and support.

Recoil is a customizable flex solution

Recoil can be tuned based on the rider's use case