Jones MTB

Made for Splitboarding

THIS IS JEREMY JONES

Regarded as the world’s best free rider and pioneer in big mountain riding, Jones is an innovator of splitboards and snowboards. Most recently known for summiting Shangri-La in the Himalayas and descending down the 2000 vertical foot, 68 degree spine.

As an environmentalist and founder of Protect our Winters (POW), Jones prefers splitboarding and on foot ascents instead of helicopters and snowmobiles.

For Jeremy - the journey is the reward.

MY ROLE

Lead designer

Color, material and finish

Merchandiser

Product line manager

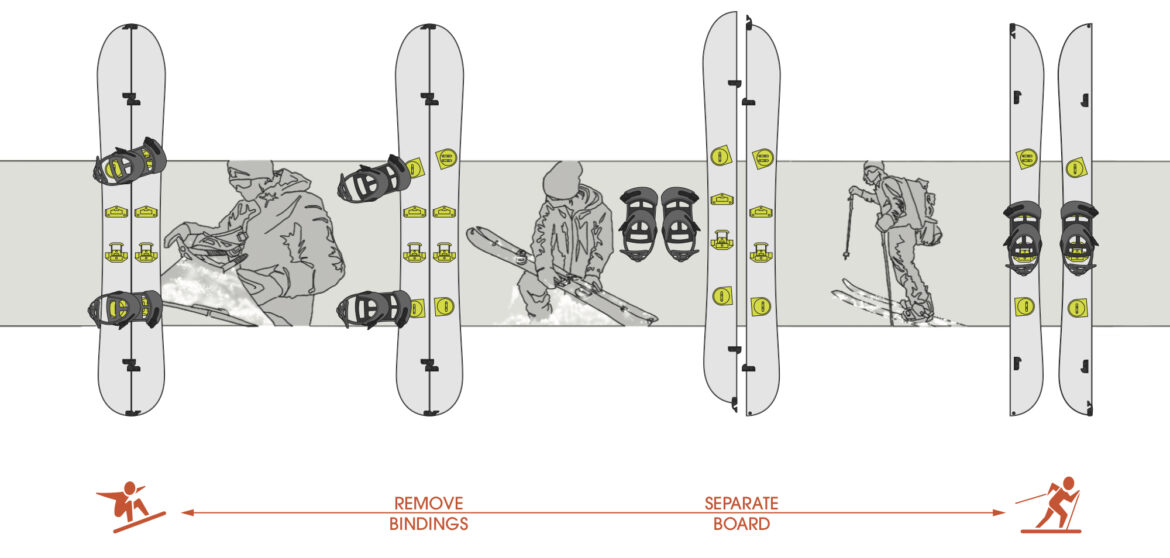

SPLITBOARDING EXPLAINED

SPLITBOARDING /ˈsplit,bôrd/

Splitboards were developed and inspired by touring skiers who climbed faster using less energy. The board splits in half becoming skis to travel uphill with the use of adhesive-backed traction pads or “skins", that are attached to each base to aid in ascent. Once at the top the splitboard is reassembled into a snowboard used to ride down.

In the past to reach inaccessible untouched terrain, snowboarders would hike with the help of snow shoes while carrying their boards making the experience cumbersome and tiring.

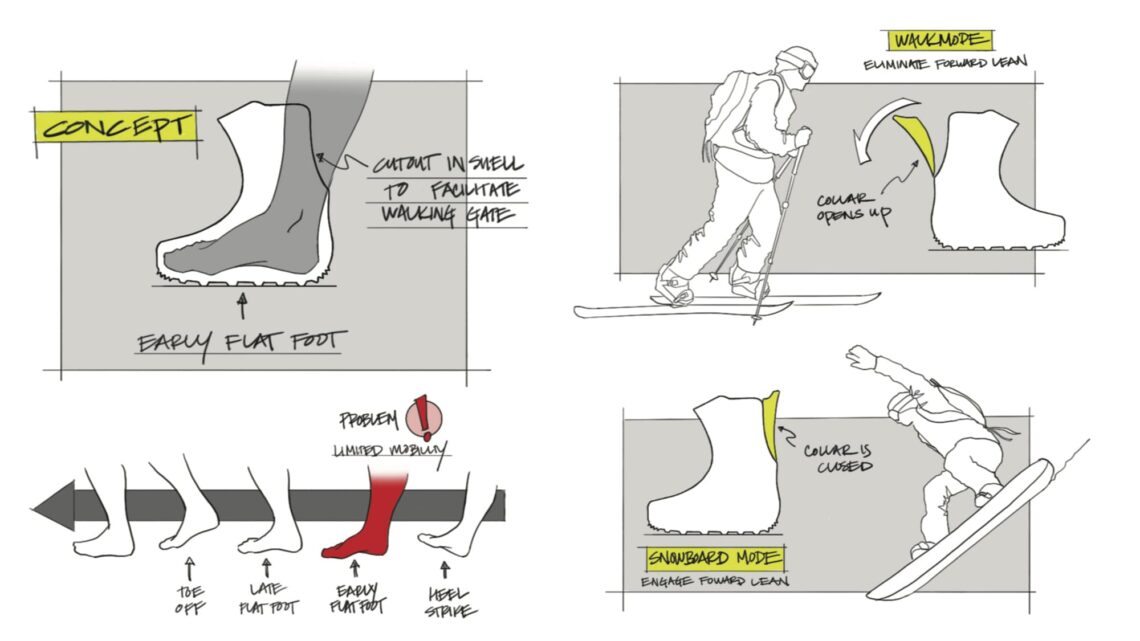

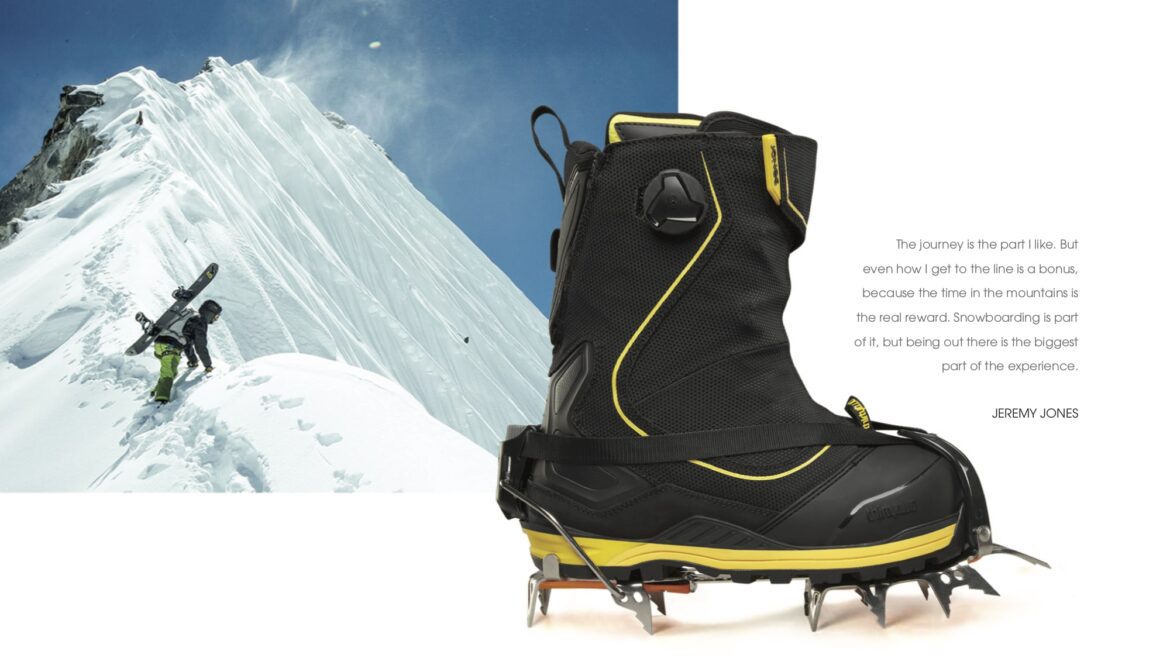

THESE BOOTS WEREN'T MADE FOR WALKING

THE CHALLENGE

As splitboarding is gaining in popularity, board technology is quickly advancing, while boot technology has been relatively stagnant barely addressing the needs of splitboarders.

Snow boots are built for snowboarding - stove pipe construction with a high collar, shaped to increase forward lean and designed to reduce heel lift. These elements restrict the ability to walk with a normal gait. With limited mobility, knees become sore, stride length is shorter, time to destination is longer and more energy is expended.

The challenge is to create a snow boot that functions equally well for snowboarding and splitboarding without compromising performance. The boot must include all technical mountaineering and snowboarding features needed by Jeremy Jones.

HIGH LEVEL GOALS:

- Mountaineering - Technical features used in climbing

- Transforming - Supportive to walkable boot

- Hybrid - A snowboot and splitboard boot

BRAINSTORMING WALK MODE

IDEATION

Brainstorming with Jeremey we discussed and identified specific pain points and user needs that were not being addressed in the splitboard space.

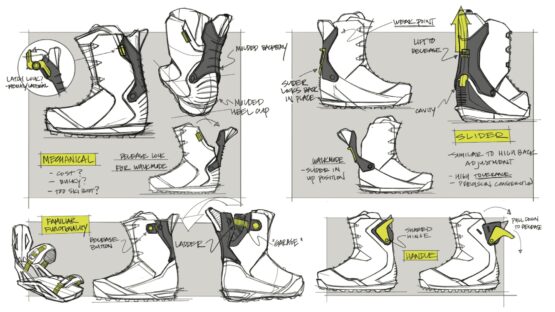

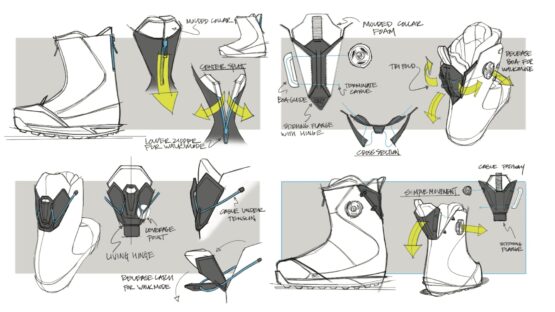

Ideation started with solutions for addressing walkability and converting from snowboard mode (maintaining forward lean) to walk mode that allows for a natural walking gait. Solutions focused around opening and closing the back of the boot alleviating the biggest restriction in movement.

The final solution utilize the BOA Fit System for ease of use and familiarity of function with users, the freedom of adjustment and the ability to service the parts.

Snowboard boots are build for support for the protection of the rider. If the boot is too soft or flexible the rider is more prone to lower leg injuries. Because of this, walkability is not considered with the final product.

Conceptualizing a "walk-friendly" boot

Exploring options for "walk mode" hinging collar with final direction utilizing Boa

THE DETAILS

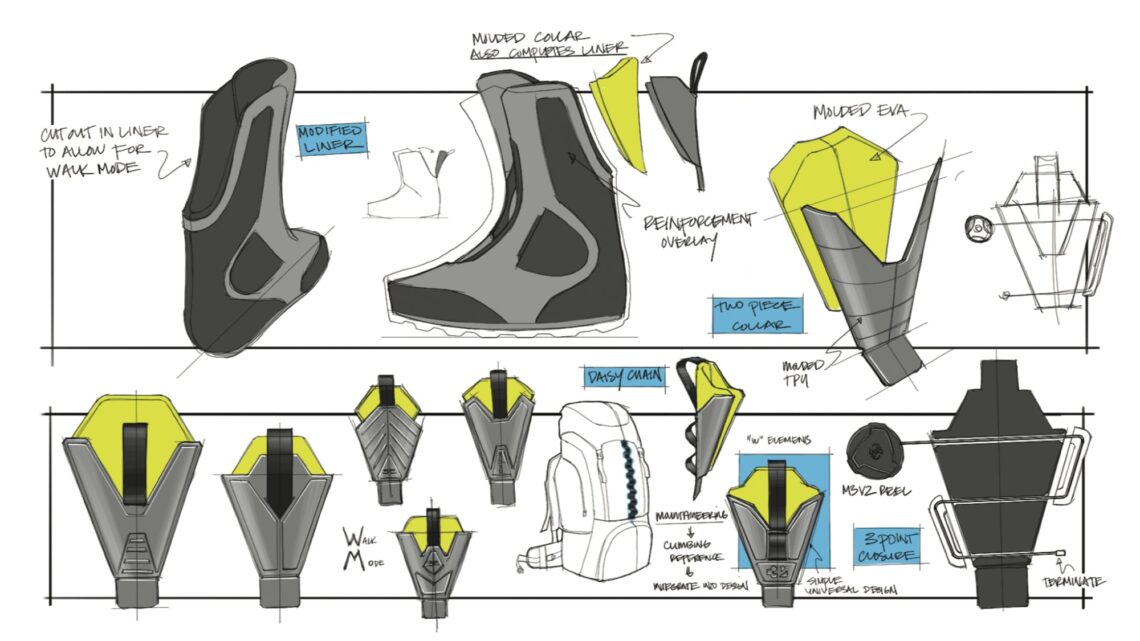

REFINEMENT

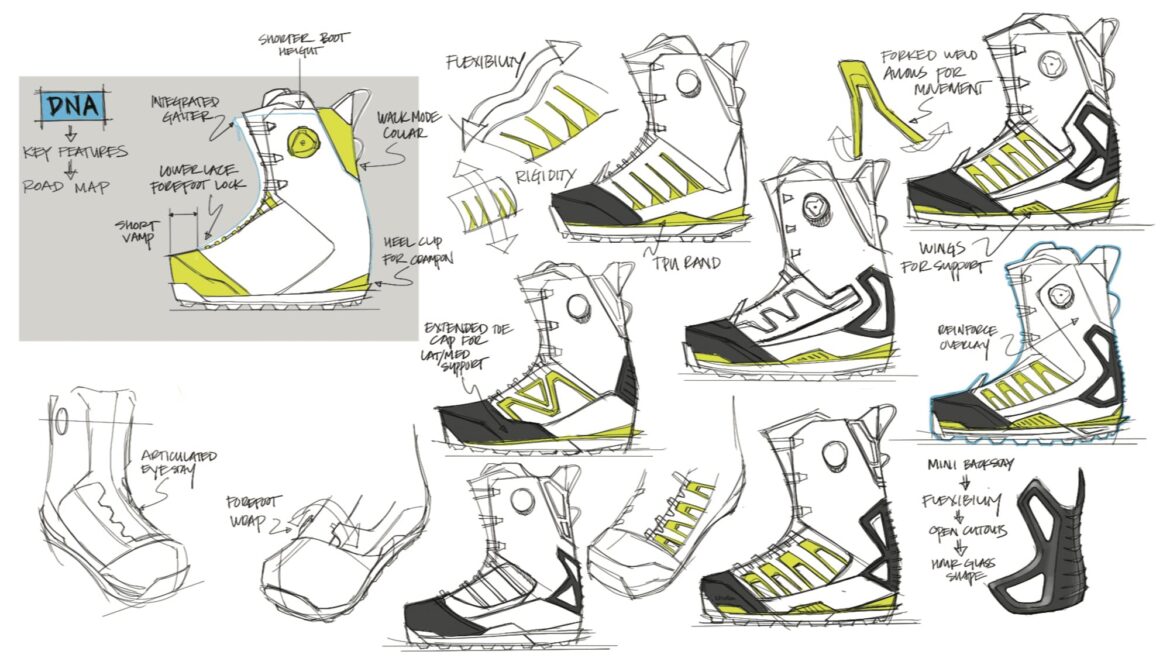

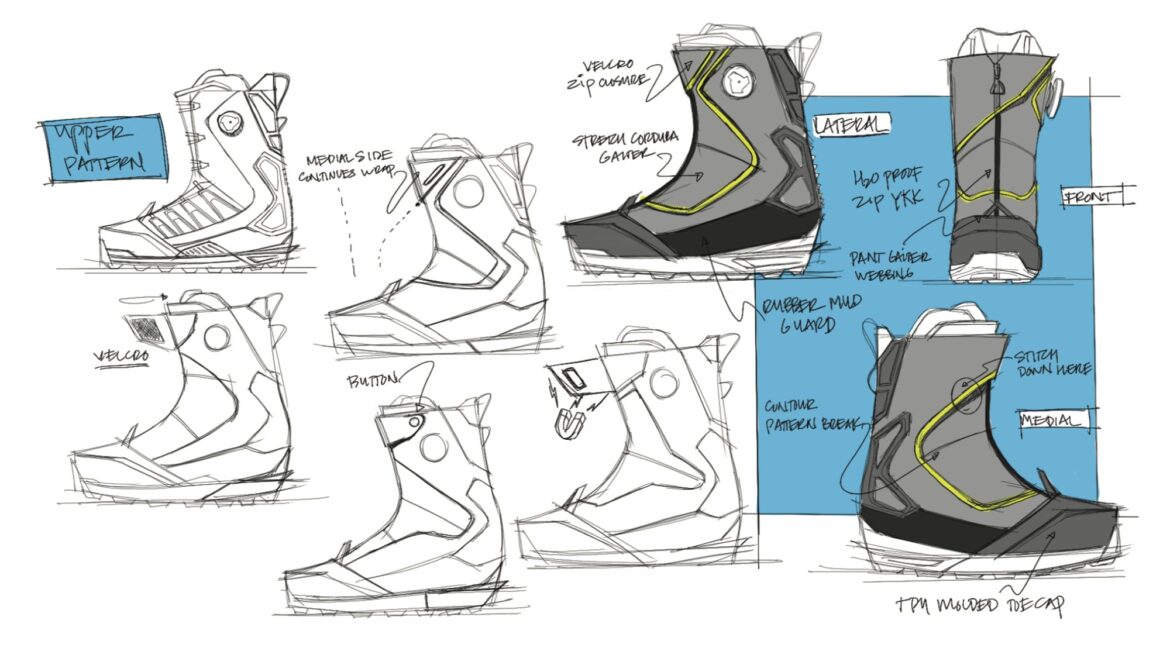

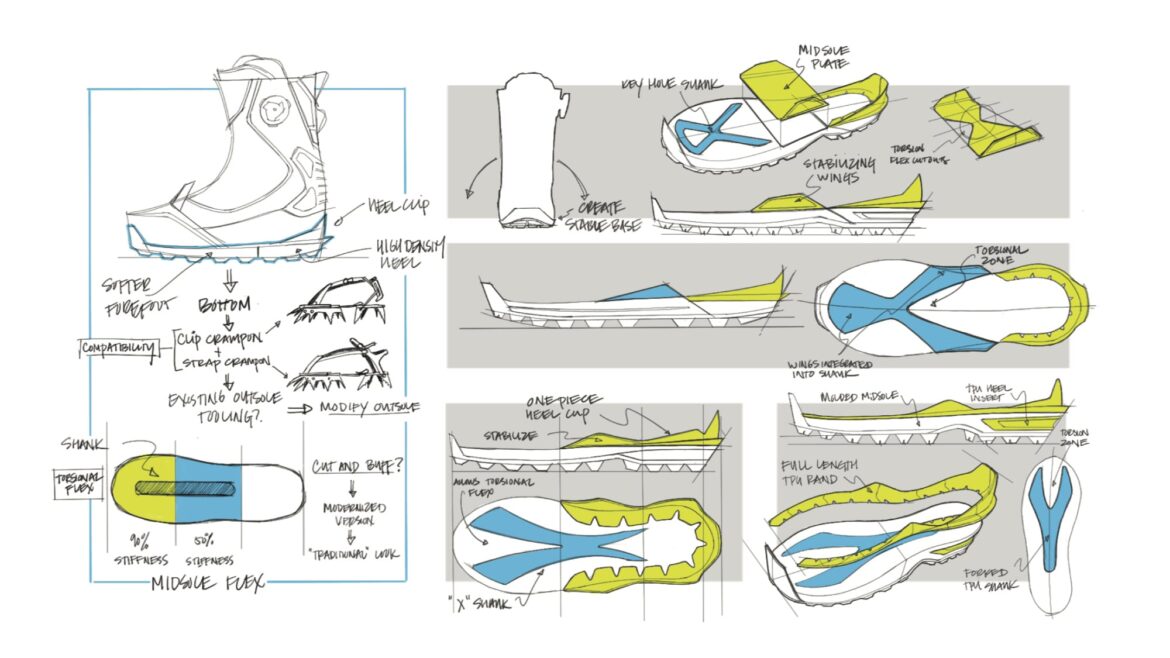

Once identifying the most viable solution for walk mode the next steps were to address Jeremy's specific needs: forefoot lockdown, rigid upper with flexibility, crampon compatibility, all-weather proofing and a variable flexing outsole.

Strategically placed welds on the quarter adds overall support to the boot while the forked design allows for movement .

A full-zip gaiter provides protection from the elements while taking inspiration from mountaineering boots.

Conceptualizing a progressively stiffer midsole

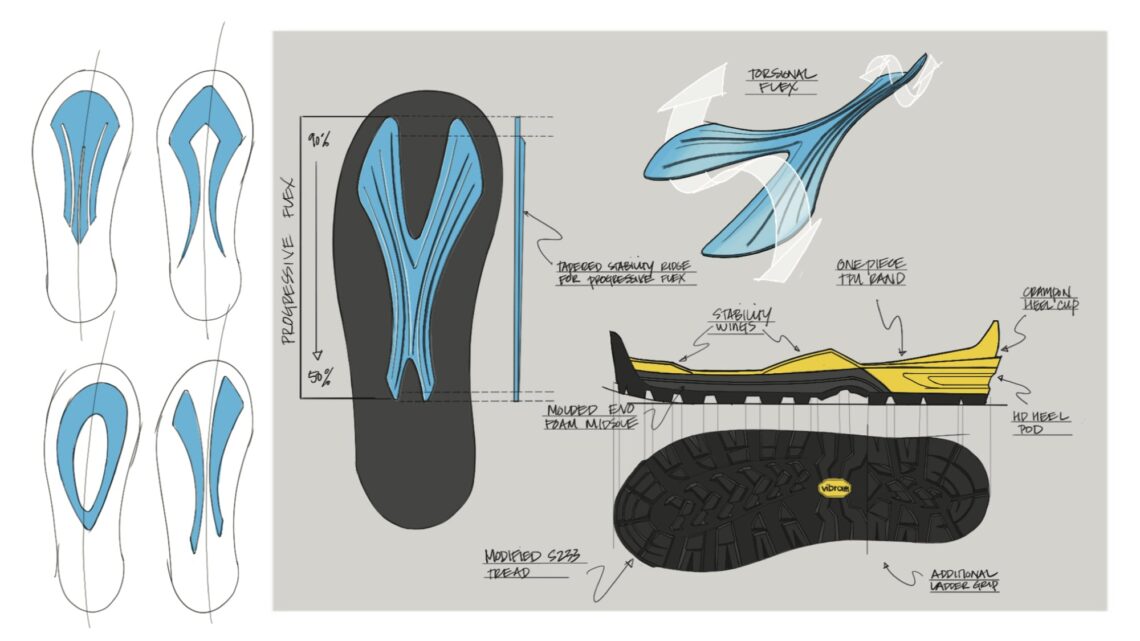

The shank is forked for torsional movement. I-beam inspired ridges taper to allow for progressively softer flex at the mid foot and stiffer support at the toe to aid in climbing and preventing foot fatigue.

PART SPLITBOARDING, MOUNTAINEERING AND SNOWBOARDING

FINAL DESIGN

Built with the revolutionary walk mode collar, the Jones MTB is the first boot in the market to address the true needs of splitboarding while performing equally well for snowboarding.

- Mountaineering - Integrating a full zip gaiter, crampon clip heel welt, Vibram mountaineering outsole, variable flex shank and molded toe cap

- Transforming - Release walk mode to extend stride length allowing for a normal gait and close walk mode to engage forward lean for snowboarding

- Hybrid - Walk Mode allows the MTB to function for both snowboarding and splitboarding

Walk Mode to Ride Mode use case

Full zip gaiter, supportive quarter, progressively flexing midsole with Vibram outsole

Walk Mode utilizing Boa and internal liner integration