UL2

Lightweight Performance

ULTRALIGHT 2

Creating the lightest snowboard boot in the market with uncompromising fit and durability in a lightweight package.

MY ROLE

Lead designer

Color, material and finish

Merchandiser

Product line manager

LIGHTER IS BETTER

THE CHALLENGE

Lighter weight means less fatigue, the less gravity is working against you. From hiking in the thin air, dangling boards on lifts, walking to cars and packing for trips - snowboarders are always looking for lightest gear. Shedding weight with outerwear, boards, boots and bindings allows for a more responsive ride.

Compromises are made for lightweight snow boots, stripping away material that sacrifices durability and structural integrity. Boot breakdown is accelerated impacting rideability. The shell becomes ill-fitting and sloppy impacting overall performance.

The challenge of this project is to create a premium lightweight snow boot without compromising durability and longevity. Build a high-performance supportive shell with a stiff flex for the all-mountain free rider.

HIGH LEVEL GOALS:

- Lightweight - Lighter and as durable as traditional snow boots

- Strength - Longevity and resistant to premature break down

- Balance - Lightweight, supportive and uncompromising performance

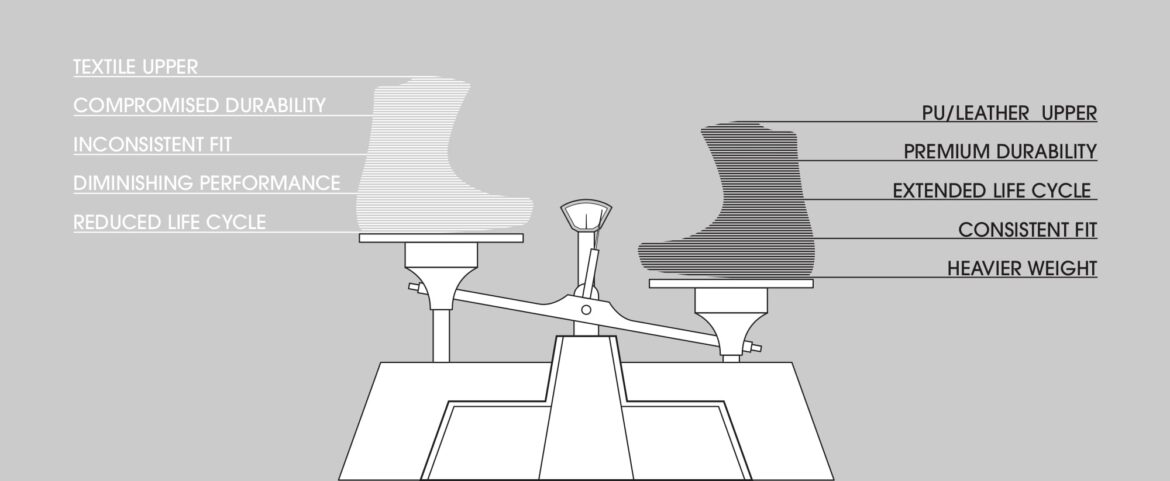

THE LIGHT WEIGHT DILEMMA

COMPARISON

Lightweight comes at a cost. With traditional boot construction the easiest way to reduce weight is by replacing heavy durable materials with lighter substitutes. While lighter is better, the compromises in construction greatly reduces boot lifespan, fit and performance.

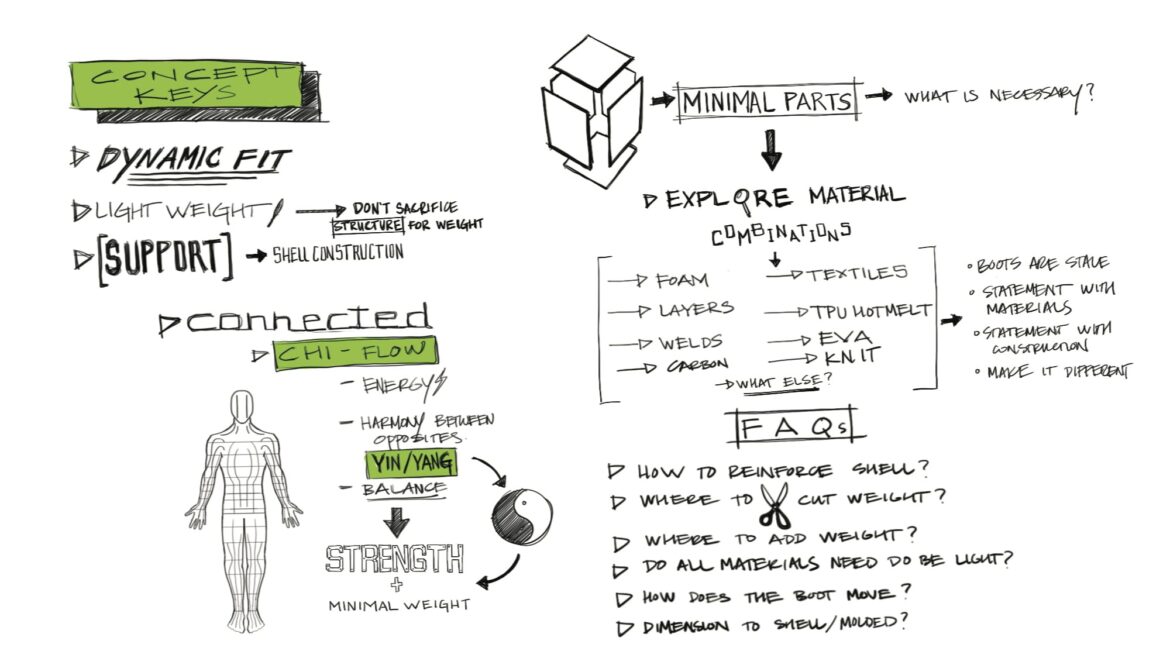

BRAINSTORMING SHELL CONSTRUCTION

IDEATION

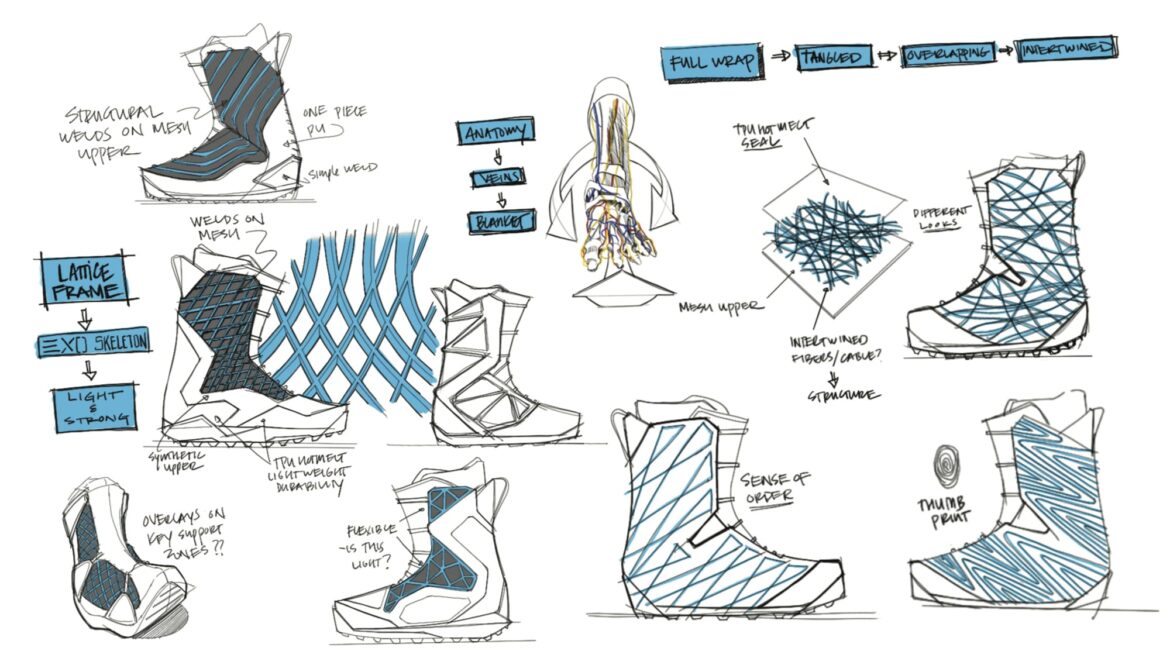

Traditional boot construction limits solutions for durability and lightweight. Brainstorming lead to exploration of unconventional materials, unique shell construction and blue sky concepts.

Frontend brainstorming notes

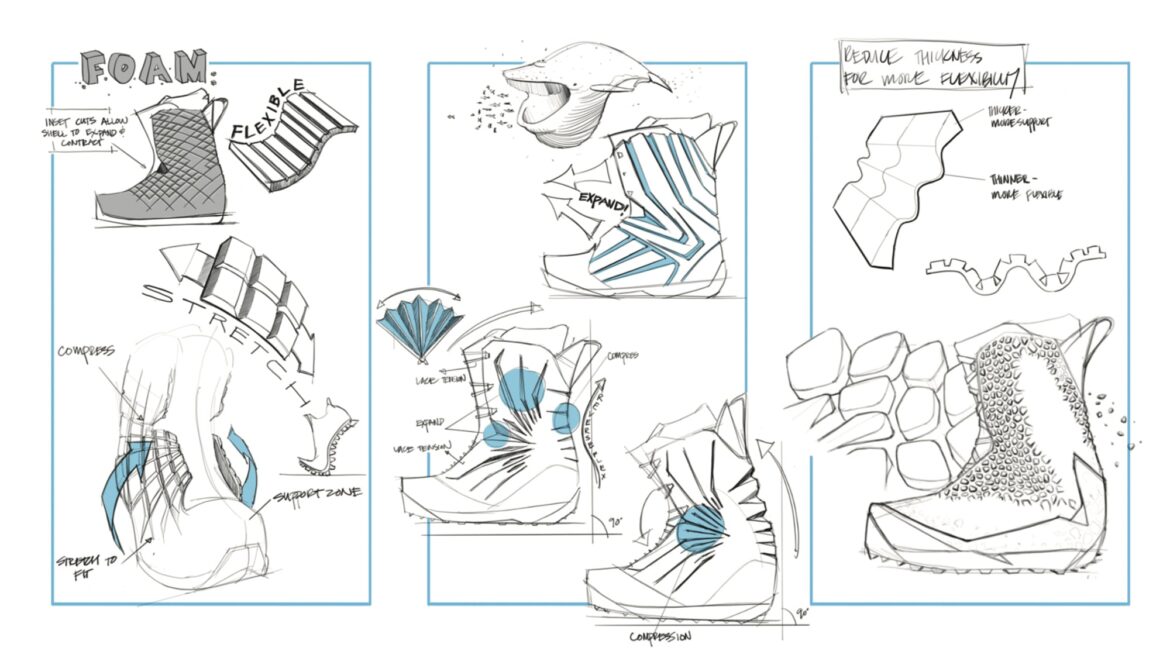

Alternative material exploration with a one piece shell

Conceptualizing light weight options considering movement and flex

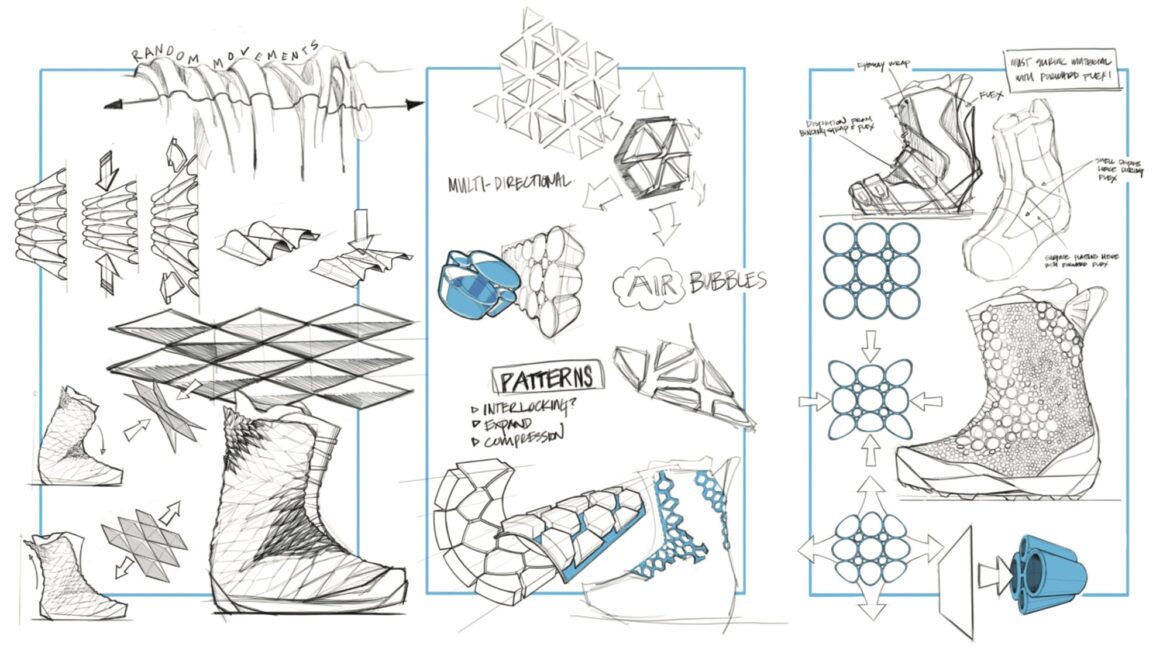

THE BUTTERFLY EFFECT

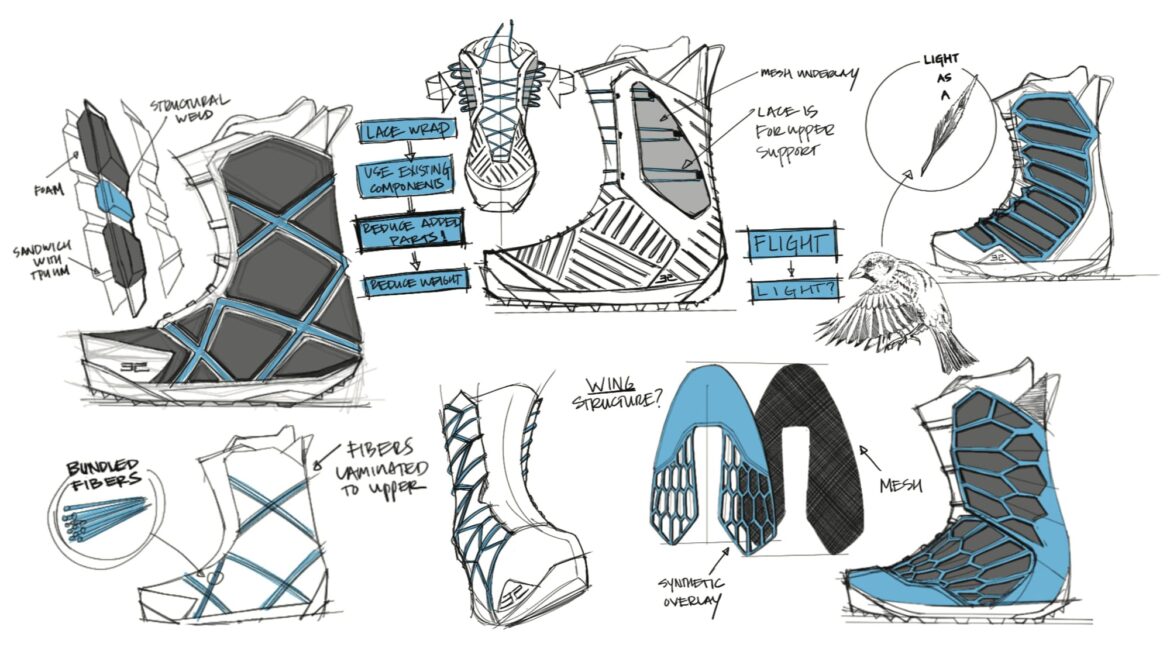

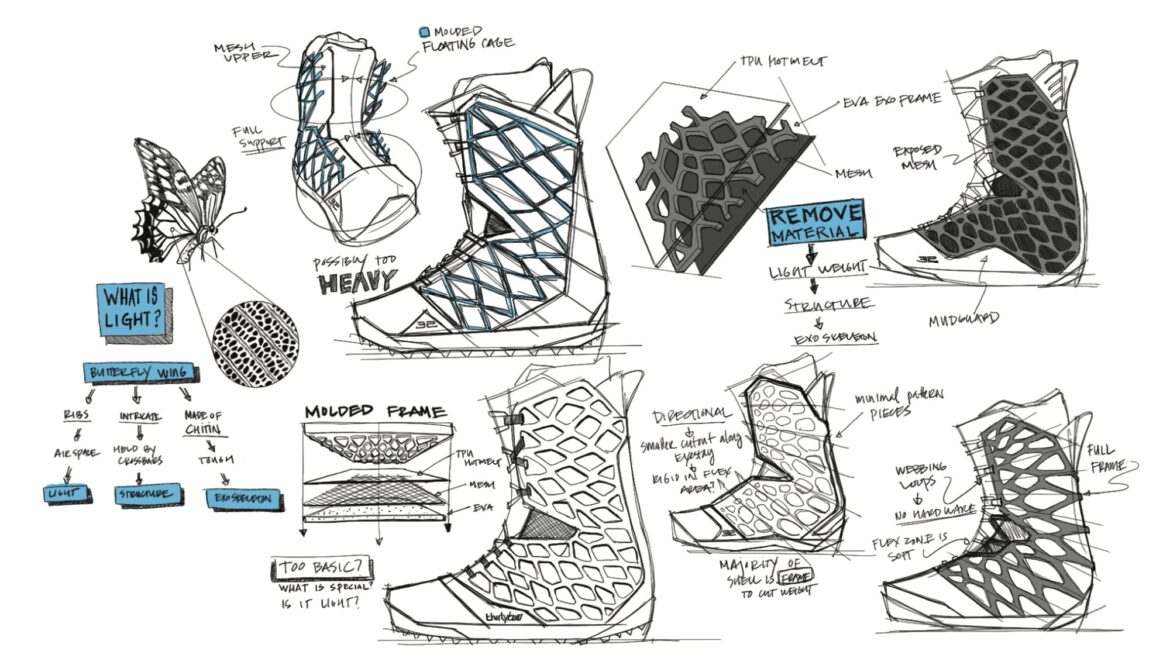

REFINEMENT

Focusing on key themes of chi and flow led to structural exoskeleton concept inspired by wings. Using the weight to strength ratio of butterfly wings the final concept speaks to lightweight strength with a lattice shell that wraps around the boot.

Lattice structured material ideation

Borrowing concepts from nature

Layered concept inspired by the incredible weight to strength ratio of butterfly wings

FINDING THE RIGHT COMBINATION

CONSTRUCTION EXPLORATION

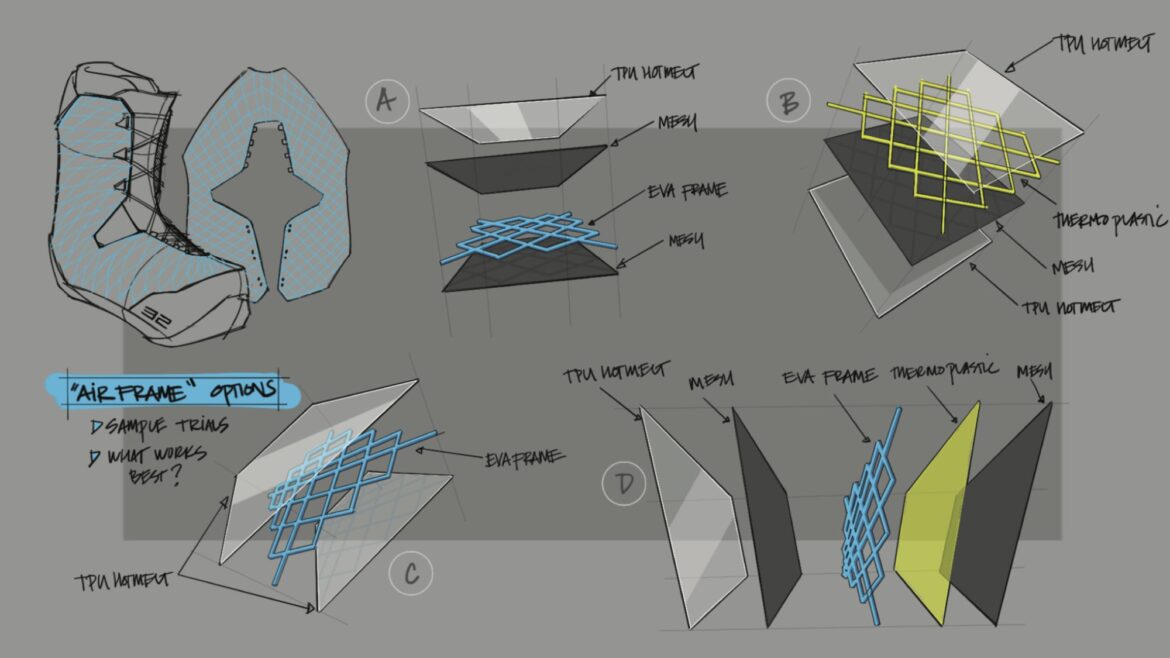

Because the shell would be fused together using compression and heat, finding the right combination of materials and specific layering order was need to ensure materials would not melt during construction. This was the most challenging aspect of the project.

Working with the factory and developers we explored and tested a dozen different concepts until we landed on a shell construction that was not only lighter but as durable as traditional snow boots.

Exploring options layered options to find the lightest material combination while still maintaining structural support needed for a snow boot

LIGHTWEIGHT AND DURABLE

FINAL DESIGN

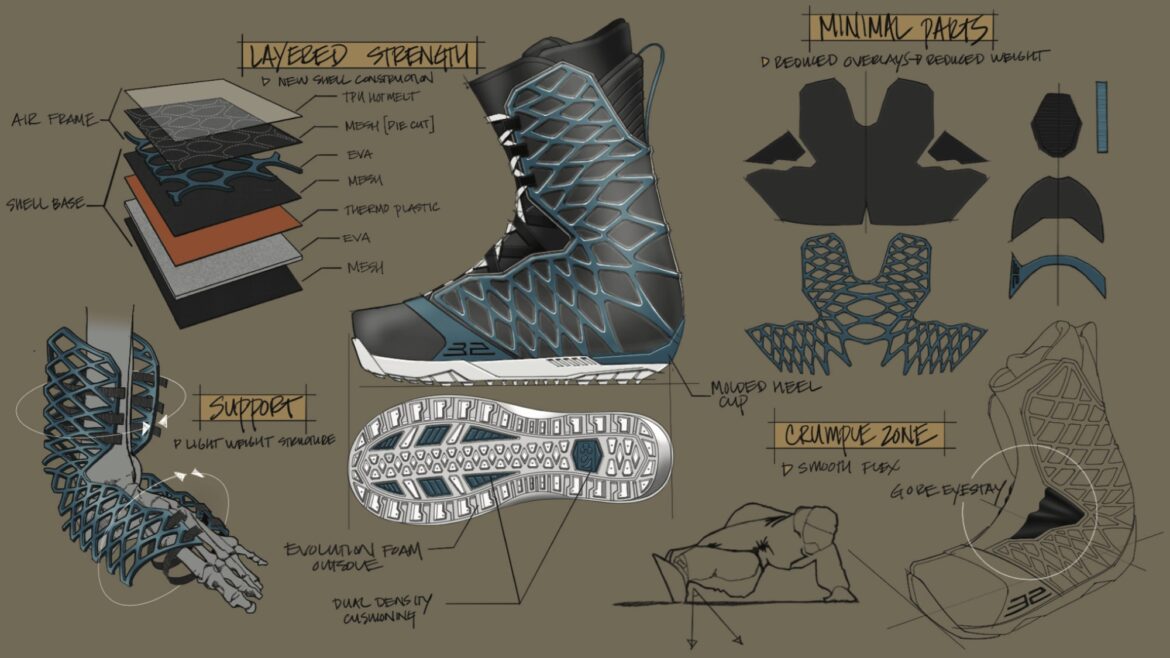

The shell construction consisted of 7 layers of reinforcement that is compressed and bonded to form and ultra strong, lightweight exoskeleton dubbed, “Air Frame”. The upper pattern was designed with minimal parts and minimal overlap to cut down on unwanted weight addressing all high level goals and resulting in the lightest snow boot in the market.

- Lightweight - Reducing overall base material thickness utilizing hot melt, mesh and thermoplastic to increase durability.

- Strength - Lattice structure wraps around the boot creating a durable support frame.

- Balance - The layered construction creates an extremely lightweight boot while the frame adds rigidity and stiffness for a response ride.

Utilizing layered materials on top of the shell base and minimal upper parts to achieve a light weight and supportive snow boot